Hydraulic lifting system

Adjustment cylinders that are installed in the application.

Our easymotion® system can adjust multiple cylinders synchronously. This is achieved by simultaneously controlling each cylinder and can be operated using an electric motor or manual crank.

Function of easymotion

An alternative to the linear adjustment with Bansbach gas springs is our linear hydraulic actuation system. Our easymotion® system can control multiple adjustment cylinders synchronously, which is achieved by simultaneously controlling each cylinder. Whether light or heavy, this system can be fitted on any application and can be customized to fit your individual needs, including multiples per application (i.e. legs on table). Numerous Bansbach gas spring components are used in the production of the easymotion® system, maintaining our high quality standard.

easymotion components

The easymotion® system consists of a hydraulic pump, adjustment cylinders, and the tubes used to connect each component. The system can be operated using an electric motor or manual crank.

E-cylinder (Requires Guiding) additional guide required, small diameter

By accessing components from the Bansbach gas spring production, a large variety of cylinders can be offered. The E-Cylinder alone is not designed to absorb side forces and also requires an additional guide.

- 150 mm

- 200 mm

- 300 mm

- 400 mm

- Stroke + 40,5

- Stroke + 45,5

- Stroke + 40,5

- Stroke + 45,5

- Stroke + 40,5

- Stroke + 45,5

- Stroke + 40,5

- Stroke + 45,5

- 10/15 mm

- 10/18 mm

- 12/22 mm

- 10/15 mm

- 10/18 mm

- 12/22 mm

- 10/15 mm

- 10/18 mm

- 12/22 mm

- 10/15 mm

- 10/18 mm

- 12/22 mm

- 1

- 2

- 4

- 1

- 2

- 4

- 1

- 2

- 4

- 1

- 2

- 4

- 100kg

- 150kg

- 225kg

- 100kg

- 150kg

- 225kg

- 100kg

- 150kg

- 225kg

- 100kg

- 150kg

- 225kg

- fast

- normal

- heavy

- fast

- normal

- heavy

- fast

- normal

- heavy

- fast

- normal

- heavy

- ZE113150-EBEX

- ZE316150-EBEX

- ZE819150-EBEX

- ZE113200-EBEX

- ZE316200-EBEX

- ZE819200-EBEX

- ZE113300-EBEX

- ZE316300-EBEX

- ZE819300-EBEX

- ZE113400-EBEX

- ZE316400-EBEX

- ZE819400-EBEX

*dependent also on selected actuation

Product features:

- Max. Weight 900kg per system

- Stroke Length: 150mm-400mm (special strokes from 30mm up to 600mm)

- Several connecting parts

- Force per E-Cylinder required to compress: 70N

- Special E-Cylinder designs available upon request

Inserted length calculation:

The length is always calculated with retracted piston rod.

The complete length of the E-Cylinder is calculated as follows:

EL1 = EL2 + ELK + ELZ

EL2: length of retracted cylinder including piston rod (see table above)

ELK: length of piston rod side connecting part

ELZ: length of cylinder side connecting part

Model:

- model 1: fast speed (6 mm per pump rotation), normal load up to 100 kg per cylinder.

- model 2: high load up to 150 kg per cylinder, normal speed (4 mm per pump rotation).

- model 4: normal speed (4 mm per pump rotation), very high load uo to 225kg per cylinder.

- The pump must be selected in correspondence with the adjustment cylinder model.

A-cylinder (Guided cylinder) additional guide not required

Adjustment cylinders, which can be attached directly to the application

A large assortment of A-Cylinder variations is available out of the gas spring production, guaranteeing our high quality components. The A-Cylinders do not require further guiding and can be mounted directly onto moveable parts of the application.

- 150mm

- 200mm

- 300mm

- 400mm

- Stroke + 179 mm

- Stroke + 179 mm

- Stroke + 179 mm

- Stroke + 179 mm

- 22/28 mm

- 22/28 mm

- 22/28 mm

- 22/28 mm

- 1

- 2

- 1

- 2

- 1

- 2

- 1

- 2

- 100 kg

- 150 kg

- 100 kg

- 150 kg

- 100 kg

- 150 kg

- 100 kg

- 150 kg

- fast

- normal

- fast

- normal

- fast

- normal

- fast

- normal

- ZA213150-ABAW

- ZA216150-ABAW

- ZA213200-ABAW

- ZA216200-ABAW

- ZA213300-ABAW

- ZA216300-ABAW

- ZA213400-ABAW

- ZA216400-ABAW

*dependent also on selected actuation

Product features:

- Max. Weight 600kg per system

- Stroke Length: 150mm – 400mm (special strokes from 30mm up to 600mm)

- Force per A-Cylinder required to compress: 70N

- Several connecting parts

- Special A-Cylinder designs available upon request

Inserted length calculation:

The length is always calculated with retracted piston rod.

The complete length of the A-Cylinder is calculated as follows:

EL1 = EL2 + ELK + ELZ

EL2: length of retracted cylinder including piston rod (see table above)

ELK: length of connecting part

ELZ: length of cylinder side connecting part

Model:

- model 1: fast speed (6 mm per pump rotation), normal load up to 100 kg per cylinder.

- model 2: high load up to 150 kg per cylinder, normal speed (4 mm per pump rotation).

- The pump must be selected in correspondence with the adjustment cylinder model.

Z-cylinder no external compression force (load) required

Combination of hydraulic adjustment cylinder and gas traction spring:

Gas spring components as well as our gas spring technology are used for this cylinder adjustment variation. The Z-Cylinder is a combination of our hydraulic adjustment cylinder and a gas traction spring. This variation allows the system to be compressed without the need of an external compression force (load). The Z-Cylinder can be installed in any position.

- 150mm

- 200mm

- 300mm

- 400mm

- Stroke + 95mm

- Stroke x 1,33 + 56mm

- Stroke + 95mm

- Stroke x 1,33 + 56mm

- Stroke + 95mm

- Stroke x 1,33 + 56mm

- Stroke + 95mm

- Stroke x 1,33 + 56mm

- 10/28mm

- 8/19mm

- 10/28mm

- 8/19mm

- 10/28mm

- 8/19mm

- 10/28mm

- 8/19mm

- 1

- 2

- 2

- 1

- 2

- 2

- 1

- 2

- 2

- 1

- 2

- 2

- 100 kg

- 150 kg

- 80kg

- 100 kg

- 150 kg

- 80 kg

- 100 kg

- 150 kg

- 80 kg

- 100 kg

- 150 kg

- 80 kg

- fast

- normal

- normal

- fast

- normal

- normal

- fast

- normal

- normal

- fast

- normal

- normal

- ZZ413150-A1ZW

- ZZ416150-A1ZW

- ZZ616150-A1ZW

- ZZ413200-A1ZW

- ZZ416200-A1ZW

- ZZ616200-A1ZW

- ZZ413300-A1ZW

- ZZ416300-A1ZW

- ZZ616300-A1ZW

- ZZ413400-A1ZW

- ZZ416400-A1ZW

- ZZ616400-A1ZW

*speed depends also on selected actuation

Product features:

- No external compression force (load) required

- Max. Weight 600kg per system

- Stroke Length: 150mm – 400mm (special strokes from 30mm up to 800mm)

- Standard Compression Force: 100N (approx 10kg)

- Attention: The max load per cylinder will be reduced accordingly. Other compression forces on request.

- Several connecting parts

Inserted length calculation:

Inserted length calculation:

The length is always calculated with retracted piston rod.

The complete length of the Z-Cylinder is calculated as follows:

EL1 = EL2 + ELK + ELZ

EL2: length of retracted cylinder including piston rod (see table above)

ELK: length of connecting part

ELZ: length of cylinder side connecting part

Model:

- model 1: fast speed (6 – 8 mm per pump rotation), normal load up to 100 kg per cylinder.

- model 2: high load up to 150 kg per cylinder, normal speed (4 – 5,3 mm per pump rotation).

- The pump must be selected in correspondence with the adjustment cylinder model.

Linear unit:

The new Bansbach linear unit can be mounted or installed at your application without any big efforts. With the linear unit, you will get a complete system with installed adjustment cylinder.

- 150

- 200

- 300

- 400

- 165

- 240

- 340

- 340

- 254

- 319

- 444

- 544

- 264

- 329

- 454

- 554

If a Z-Cylinder in selected: B = Stroke x 1,33 + 121 und B* = Stroke x 1,33 + 131

- Stroke from 150 to 400 mm

- E-Cylinder model 1 and 2 and

- Z-Cylinder model 2, Ø 8/19 suitable

- Different adapter plates for fixing

- Stroke loads of up to 150 kg / Cylinder

- Anodized aluminium

- Force required to compress: 100N

Adapter plate for linear unit:

The adapter plate can be adjusted exactly according to your requirements.

Guide column

Due to its modular construction, the Bansbach Guide Column is extremely flexible and can be used in numerous applications without regard to the number of columns needed. Nearly all requirements can be met with the variable lengths of the traverse members offered. The piston rod, which is secured against possible rotation, offers additional security.

Product features:

- Anti-Rotation

- Available in any length (Note: please consider the minimum length in relation to the stroke length)

- Hose connection possible on both sides

- Suitable for all adjustment cylinders

- force required to compress: 100N

Pumps

Pumps for operating easymotion® cylinders synchronously

Product features:

- Pumps for operating 1-6 cylinders

- Max. weight: 900kg per system (model 4)

- Made of anodized aluminum

- Operation by crank or electric motor

- Mounting in any position is possible

Cylinder model 1

Fast speed

Normal weight

- 1

- 2

- 3

- 4

- 5

- 6

cylinder

- 150mm

- 200mm

- 300mm

- 400mm

- 150mm

- 200mm

- 300mm

- 400mm

- 150mm

- 200mm

- 300mm

- 400mm

- 150mm

- 200mm

- 300mm

- 400mm

- 150mm

- 200mm

- 300mm

- 400mm

- 150mm

- 200mm

- 300mm

- 400mm

(BxHxT)

- 80x30x276,5mm

- 80x30x322,5mm

- 80x30x416,5mm

- 80x30x510,5mm

- 80x30x276,5mm

- 80x30x322,5mm

- 80x30x416,5mm

- 80x30x510,5mm

- 68x56x276,5mm

- 68x56x322,5mm

- 68x56x416,5mm

- 68x56x510,5mm

- 68x56x276,5mm

- 68x56x322,5mm

- 68x56x416,5mm

- 68x56x510,5mm

- 120x60x276,5mm

- 120x60x322,5mm

- 120x60x416,5mm

- 120x60x510,5mm

- 120x60x276,5mm

- 120x60x322,5mm

- 120x60x416,5mm

- 120x60x510,5mm

- 100 kg

- 200 kg

- 300 kg

- 400 kg

- 500 kg

- 600 kg

- PE119150

- PE119200

- PE119300

- PE119400

- PE219150

- PE219200

- PE219300

- PE219400

- PE319150

- PE319200

- PE319300

- PE319400

- PE419150

- PE419200

- PE419300

- PE419400

- PE519150

- PE519200

- PE519300

- PE519400

- PE619150

- PE619200

- PE619300

- PE619400

Cylinder model 2

Heigh load

Normal speed

- 1

- 2

- 3

- 4

- 5

- 6

cylinder

- 150mm

- 200mm

- 300mm

- 400mm

- 150mm

- 200mm

- 300mm

- 400mm

- 150mm

- 200mm

- 300mm

- 400mm

- 150mm

- 200mm

- 300mm

- 400mm

- 150mm

- 200mm

- 300mm

- 400mm

- 150mm

- 200mm

- 300mm

- 400mm

(BxHxT)

- 80x30x348,5mm

- 80x30x418,5mm

- 80x30x560,5mm

- 80x30x702,5mm

- 80x30x348,5mm

- 80x30x418,5mm

- 80x30x560,5mm

- 80x30x702,5mm

- 68x56x348,5mm

- 68x56x418,5mm

- 68x56x560,5mm

- 68x56x702,5mm

- 68x56x348,5mm

- 68x56x418,5mm

- 68x56x560,5mm

- 68x56x702,5mm

- 120x60x348,5mm

- 120x60x418,5mm

- 120x60x560,5mm

- 120x60x702,5mm

- 120x60x348,5mm

- 120x60x418,5mm

- 120x60x560,5mm

- 120x60x702,5mm

- 150 kg

- 300 kg

- 450 kg

- 600 kg

- 600 kg

- 600 kg

- PA119150

- PA119200

- PA119300

- PA119400

- PA219150

- PA219200

- PA219300

- PA219400

- PA319150

- PA319200

- PA319300

- PA319400

- PA419150

- PA419200

- PA419300

- PA419400

- PA519150

- PA519200

- PA519300

- PA519400

- PA619150

- PA619200

- PA619300

- PA619400

Model 4: pump length = 2x stroke + 136,5mm

Attention: In case of a double system, the pump length will be accordingly shorter:

Model 1: 150mm stroke = 226,5mm, 200mm stroke = 248,5mm, 300mm stroke = 296,5mm, 400mm stroke = 342,5mm

Model 2: 150mm stroke = 262,5mm, 200mm stroke = 296,5mm, 300mm stroke = 368,5mm, 400mm stroke = 438,5mm

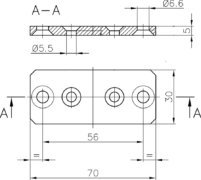

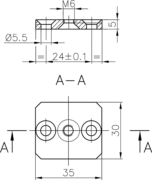

Pump mounting holes:

Bansbach Actuation

It’s your choice: comfortable adjustment by electric motor or adjustment 100% independent of electricity. Our easymotion® systems can be operated using either a manual crank or an electric motor (230V or 110V). An adjustment speed of up to 44mm/sec can be reached, depending on the load and the corresponding electric motor.

- max. weight: 900kg

- max. speed: 17,3 mm/sec

- Current Consumption at Max Weight: 7A

- Motor speed: 65 1/min

- Max. Torque 10 Nm

- B x H x T: 13 x 10 x 18,5

- Integrated safety feature if overloaded or short circuited, CE-Certification

- max. weight: 400kg

- max. speed: 44 mm/sec

- Current Consumption at Max Weight: 9A

- Motor speed: 165 1/min

- Max. Torque 5 Nm

- B x H x T: 13 x 10 x 18,5

- Integrated safety feature if overloaded or short circuited, CE-Certification

- CRANK K1:

- Hinged

- Radius 125 mm

- Stroke per rotation: 6 mm (Model 1), 4 mm (Model 2)

- CRANK K2:

- Hinged

- Radius 125 mm

- Stroke per rotation: 6 mm (Model 1), 4 mm (Model 2)

- removable

It’s your choice: comfortable adjustment by electric motor or adjustment 100% independent of electricity. Our easymotion® systems can be operated using either a manual crank or an electric motor (230V or 110V). An adjustment speed of up to 44mm/sec can be reached, depending on the load and the corresponding electric motor.

- 900 kg

- 600 kg

- 400 kg

- 400 kg

- 300 kg

- 250 kg

- 200 kg

- 200 kg

- 150 kg

- 225 kg (4*)

- 150 kg (4*)

- 100 kg (4*)

- 150 kg (3*)

- 100 kg (3*)

- 150 kg (2*)

- 100 kg (2*)

- 150 kg (2*)

- 100 kg (2*)

- 3,3 mm/sec

- 5,8 mm/sec

- 8,7 mm/sec

- 14,7 mm/sec

- 22 mm/sec

- 11,6 mm/sec

- 17,3 mm/sec

- 29,3 mm/sec

- 44 mm/sec

- M1

- M1

- M1

- M3

- M3

- M1

- M1

- M3

- M3

- 4

- 2

- 1

- 2

- 1

- 2

- 1

- 2

- 1

- Standard

- Standard

- Standard

- Standard

- Standard

- Double**

- Double**

- Double**

- Double**

- 500 kg

- 300 kg

- 250 kg

- 200 kg

- 150 kg

- 225 kg (4*)

- 150 kg (2*)

- 100 kg (3*)

- 150 kg (2*)

- 100 kg (2*)

- 3 mm/U

- 4 mm/U

- 6 mm/U

- 8 mm/U

- 12 mm/U

- K1/K2

- K1/K2

- K1/K2

- K1/K2

- K1/K2

- 4

- 2

- 1

- 2

- 1

- Standard

- Standard

- Standard

- Double**

- Double**

Accessories

- Order Number: EM-AC-KIT

- 250 ml Bansbach hydraulic-oil

- Refill syringe for easymotion

- lock nuts, clamp rings, tube bushing, tube cutter

- very simple assembly

- pump and cylinder will be delivered ready for use

- no filling, no ventilation

- plug in and get started

- Order number: EM-AC-BS1

- Bracket to mount the A-Cylinder on the application

- Distance between the boreholes: 40 mm

- 2 clamps per A-Cylinder recommended

- Order number: EM-AC-SC1

- Diameter 4 mm

- Max length per cylinder 5 m

- Ratio between the single tubes max 5:1

- Min bending radius 50 mm

- If stroke <100 mm: max tube length 1500mm

- also available in filled and weld-shut condition (max 1500 mm)

- Order number: EM-AC-FU3

- Foot of plastic

- Height adjustment possible

- Order number: EM-AC-FU2

- Foot of aluminum

- Height adjustment possible

- Prevents the uncontrolled running in of the cylinders at damage or disruption of the tubes

- Available as an option for all easymotion systems (standard at 900kg)

- Fitting connecting parts: AB/ZB and AW/ZW

- Max force: 300kg

- Fitting connecting parts: AB/ZB and AW/ZW

- Max force: 100kg

- Fitting connecting parts: AB/ZB and AW/ZW

- Max force: 100kg

Do you need help?

We are there for you

Contact personthe product is precisely adapted to your requirements in order to ensure optimal function. We are happy to support and advise you in the selection of the right product.

With our “Technical Support” you have a direct line to our technicians, who will competently assist you. If you have any questions about offers, availability or prices, our commercial support will be happy to assist you.

FAQs

Are Bansbach gas springs ROHS compliant?

Yes, they are fully ROHS compliant and also meet all guidelines, export/import regulations and goals of other company programs that we are aware of.

Can a gas spring made to customer specifications be returned?

Bansbach gas springs are manufactured to order – from mostly stock components. Cancellation, exchange or return is therefore not possible.

In case of free delivery, we will gladly take over the disposal – without charge – for you.

Can gas springs be disposed of in household waste?

No, gas springs are mainly made of metal. Please observe our disposal instructions.

Can gas springs be used in the food industry?

With the high-quality stainless steel gas springs in V4A, the high requirements of the food industry are met. Food-grade oil (FDA oil) is optionally available.

Can the speed/damping of the gas spring be influenced?

By selecting the appropriate nozzle bore and oil viscosity, the speed and damping of the gas spring can be adapted to the application.

Do Bansbach gas springs have to be stored with the piston rod pointing downwards?

Bansbach gas springs can be stored in any position.

Does a gas spring need to be protected from dirt?

The piston rod must be protected against impact, scratches and contamination – especially paint application. Damage to the surface will destroy the sealing system. If necessary, a wiper or a protective tube should be provided.

Does a gas spring need to be serviced?

No, Bansbach gas springs are maintenance-free. The piston rod must not be greased or oiled.

How do I find my personal contact person?

Bansbach easylift GmbH

Bararossastrasse 8

D-73547 Lorch

Phone: +49 (0) 7172/9107-0

Fax: +49 (0) 7172/9107-44

E-Mail: info@bansbach.de

You can find a contact person on site

Contact form

How high can the internal pressure of a gas spring be?

Depending on the series and the desired extension force, this can be up to approx. 300 bar.

How much is the weight of a gas spring?

Due to the wide range of products, the weights vary greatly.

Diameter piston rod / cylinder:

Ø3/8; Ø4/12; Ø6/15; Ø6/19; Ø6/22; Ø8/19; Ø8/22

Weight

100 g – 500 g

———-

Diameter piston rod / cylinder:

Ø8/28; Ø10/22; Ø10/28; Ø12/28; Ø14/28

Weight

200 g – 1000 g

———-

Diameter piston rod / cylinder:

Ø16/28; Ø10/40; Ø12/40; Ø14/40; Ø20/40; Ø30/70

Weight

500 g – 8000 g

In which colors are Bansbach gas springs available?

The piston rod and the cylinder are supplied in black (standard).

On request, our cylinders are available in all RAL colors. Exception: stainless steel

In which temperature ranges can Bansbach gas springs be used?

For ambient temperatures from -30°C to +80°C.

For other temperature ranges (down to -55°C or up to +200°C) special seal sets are available.

Is it possible to repair a gas spring?

No, because it is a closed system that is under high pressure and must not be opened.

Is the extension force of the gas spring temperature-dependent?

For physical reasons, the extension force of the gas spring changes by approx. 3.3% per 10°C (base + 20°C).

What does the index number (e.g. – -001/100 N) at the end of the article designation of the gas spring mean?

This is a code assigned internally by Bansbach for unambiguous reproducibility of the gas spring.

What materials are Bansbach gas springs made of?

Gas springs consist of piston rod, cylinder tube, connecting parts, turned parts, seals, oil, grease and nitrogen. Piston rods and cylinder tubes are made of steel and are CeramPro® or powder coated in our company. Connecting parts and turned parts are made of lead-free steel or lead-free aluminum.

Seals, oils, greases do not contain substances that are on the list of critical or hazardous substances. Nitrogen is an inert gas that neither burns nor poses any other health hazards. Bansbach gas springs therefore comply with current and, as far as we know, planned laws and regulations.

They comply for example with the RoHS Directive, WEEE Directive, Directives 2003/11/EC, 2002/95/EC, 2002/96/EC. They are not covered by Directives 94/9/EC, 97/23/EC, and 98/37/EC, nor by UN 3164, TRGS 220, and UL 60601-1.

Verification that Bansbach gas springs in the end product comply with national or international laws and regulations remains the responsibility of our customers or the user.

What service life/running performance can I expect from a Bansbach gas spring?

On average, Bansbach gas springs are designed for 50,000 – 100,000 double strokes.

Depending on the design, installation and effective stroke, several 100,000 strokes can also be achieved.

For other products please contact us.

Which stroke lengths are possible for the gas springs?

Depending on the series and design of the gas spring, the stroke length can be freely selected between 10 mm and 1000 mm. Other variations possible, please contact us.

With our “Technical Support” you have a direct line to our technicians, who will competently assist you. If you have questions about offers, availability or prices, our commercial support will be happy to assist you.