Main Type B

Main Type B

In this basic type of lockable spring, the locking is achieved through gas and remains flexible in both directions. When the valve is closed, this type of spring can be positioned anywhere along the stroke, but the locking is elastic. Depending on the amount of force applied, a displacement may take place when the gas spring is locked. Although the gas spring is locked, there will be a comfortable damping.

Spring locking

In this basic type of lockable spring, the locking is achieved through gas and remains flexible in both directions. When the valve is closed, this type of spring can be positioned anywhere along the stroke, but the locking is elastic. Depending on the amount of force applied, a displacement may take place when the gas spring is locked. Although the gas spring is locked, there will be a comfortable damping.

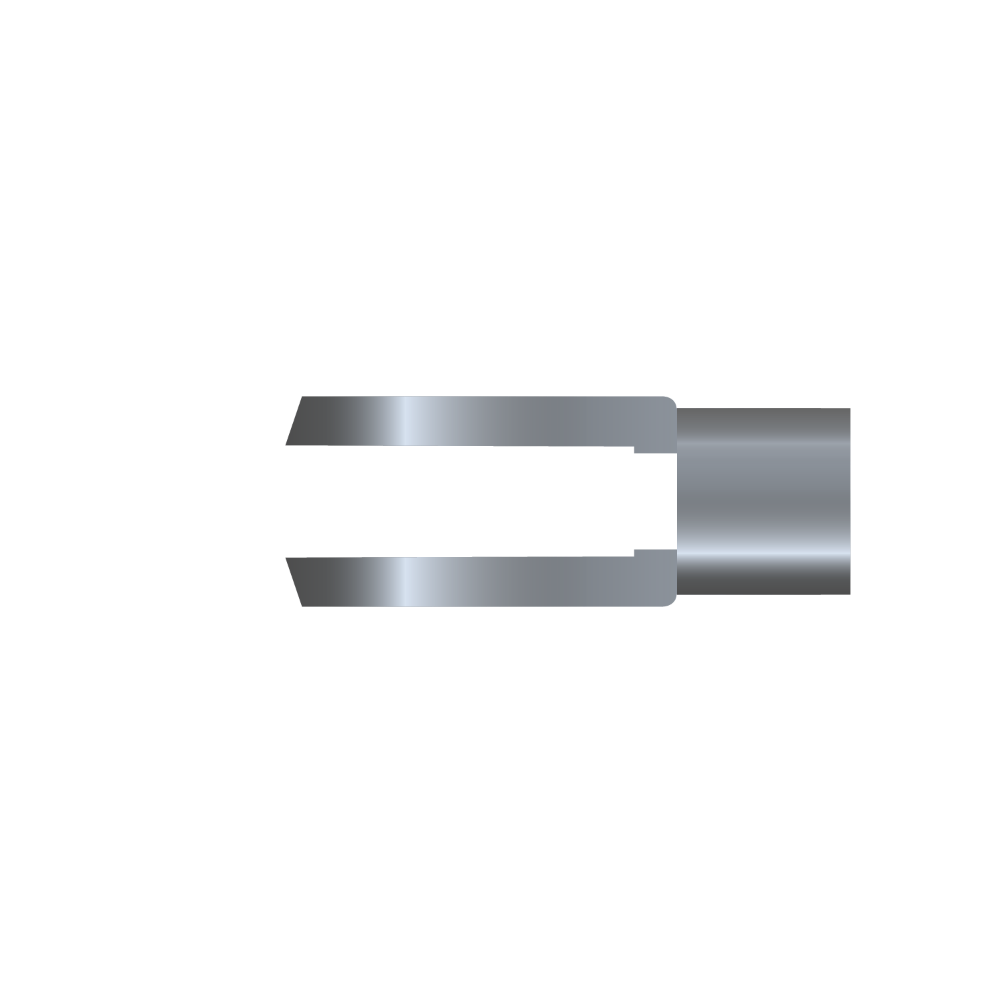

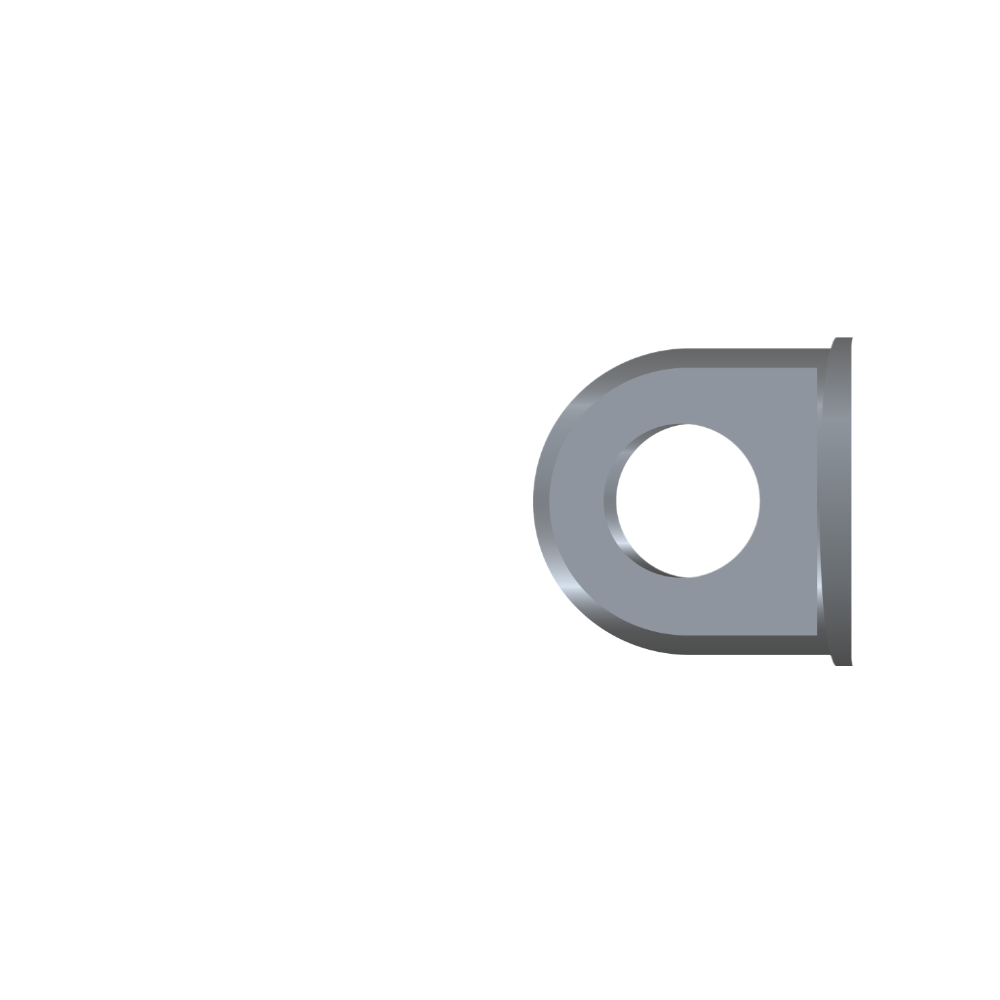

cylinder/piston rod:

Possible article no.:

piston rod

- K0 = MF10x1x18

- O0 = MF14x1,5×20

- W0 = MF 8x1x16

cylinder

- see connecting parts

- B

- – = normal 0 = fast

- 7 = slow

- K = short release

- Rel. travel

- < 1 mm instead of

- < 3,5 mm

- B = special

- N = stainless steel

- F = with valve

- inside the cylinder

- 6= 6/15

- C= 6/19

- D= 6/22

- 0= 8/19

- 1= 8/22

- E= 8/28

- 2= 10/22

- 3= 10/28

- A= 10/40

- 5= 14/28

- B= 14/40

- 10-150

- 10-150

- 10-150

- 10-300

- 10-300

- 10-300

- 10-700

- 10-700

- 10-700

- 30-700

- 30-800

- Stroke x 2 +52

- Stroke x 2 +63

- Stroke x 2 +64

- Stroke x 2 +75

- Stroke x 2 +75

- Stroke x 2 +87

- Stroke x 2 +81

- Stroke x 2 +94

- Stroke x 2 +99

- Stroke x 2 +94

- Stroke x 2 +96

- 30

- 20

- 10

- 33

- 23

- 13

- 39

- 21

- 8

- 52

- 18

- *see below

- 50-400

- 50-400

- 50-400

- 40-700

- 40-700

- 40-700

- 50-1300

- 50+1300

- 50-1300

- 150-2600

- 150-2600

With the index no. – only necessary for repeating orders – we can reproduce exactly the same gas spring which has already been produced. You will receive the index no. with the order confirmation / invoice.

EL1

The total length is calculated when the piston rod is extended. Please add the length of the connecting parts in order to find out the total length.

EL2

length EL2 = measured without hinge eyes and threads.

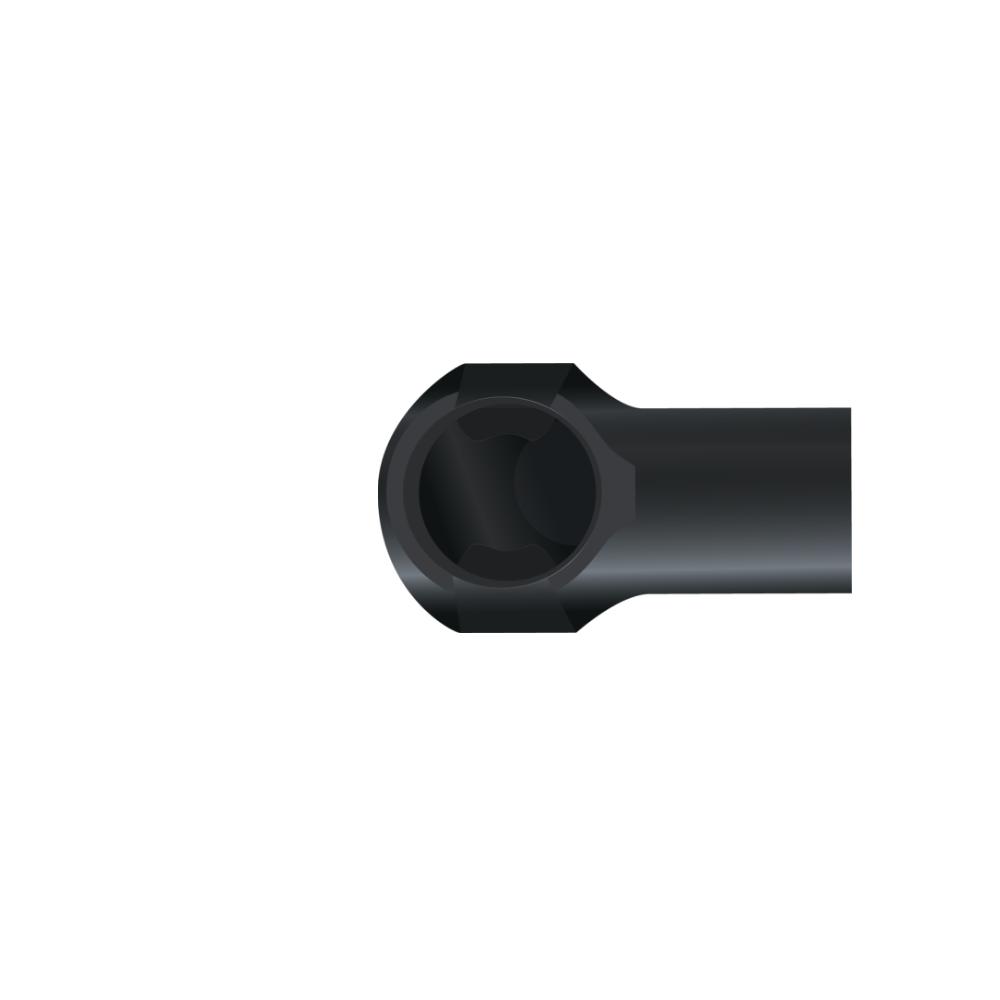

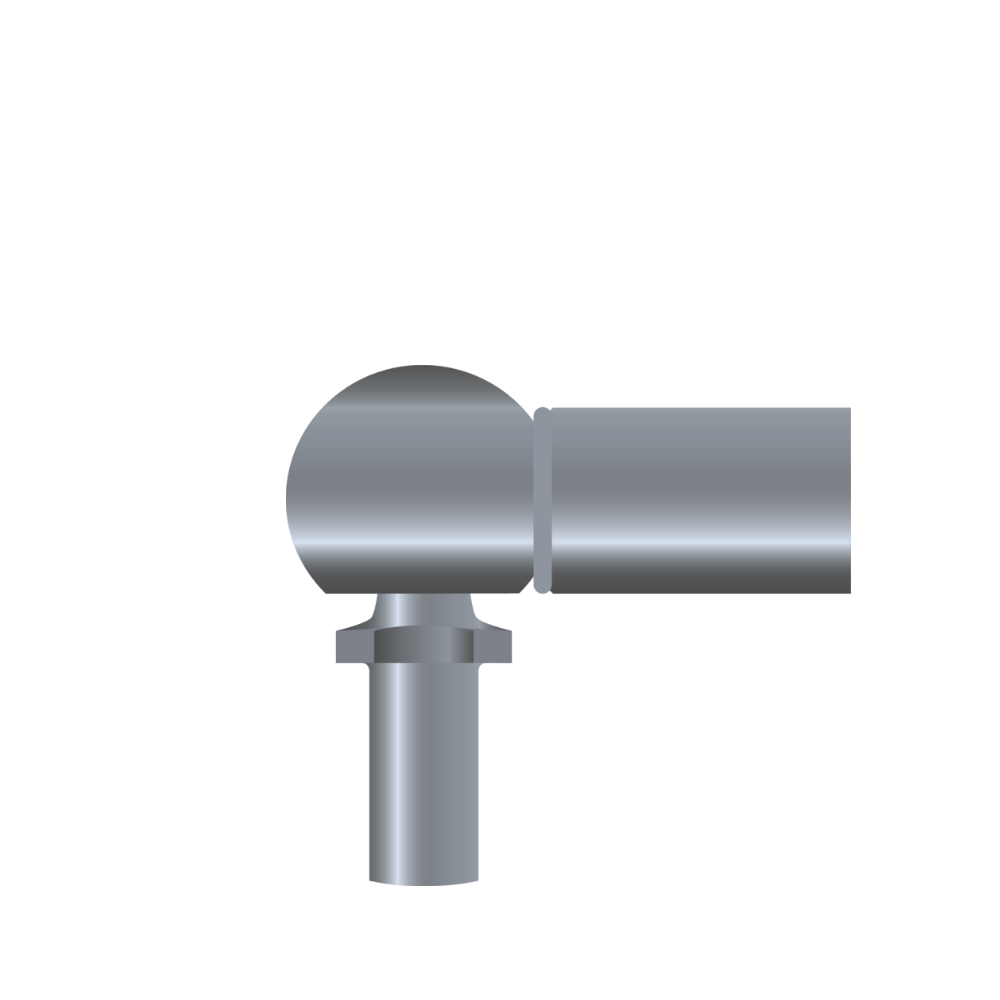

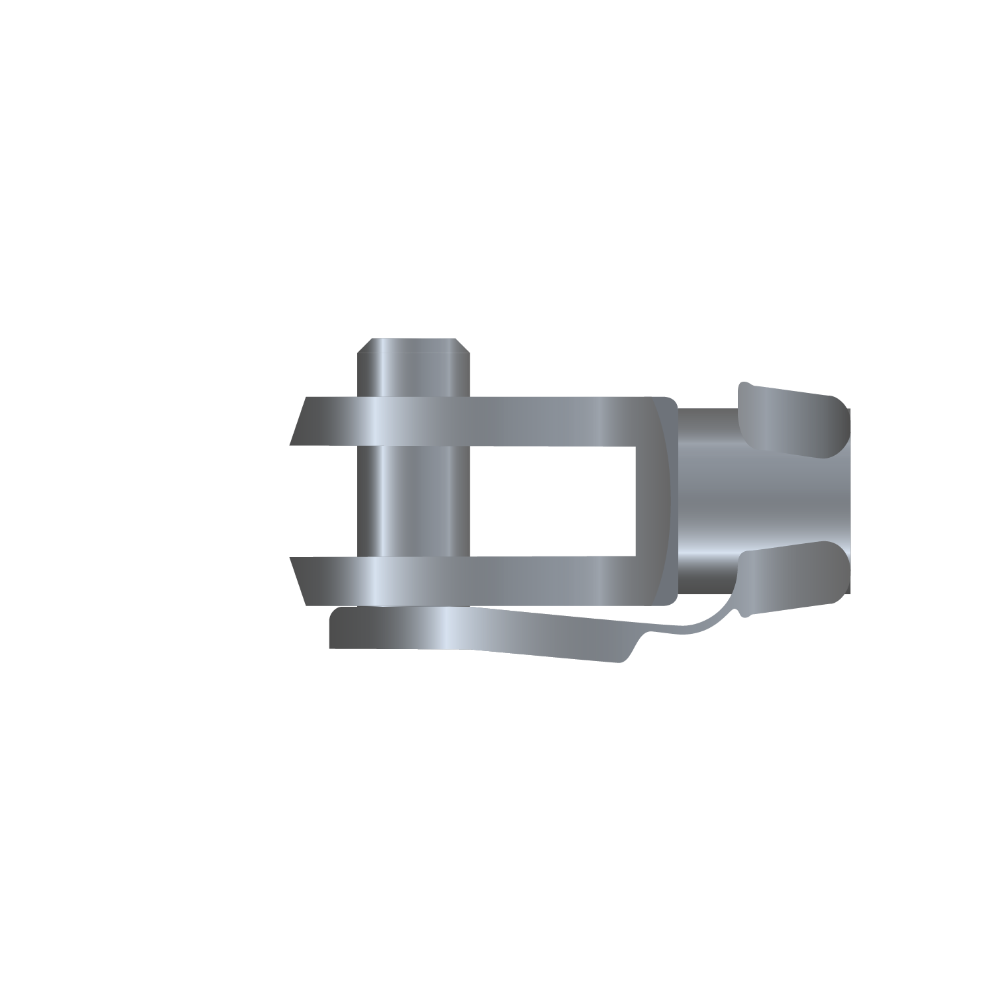

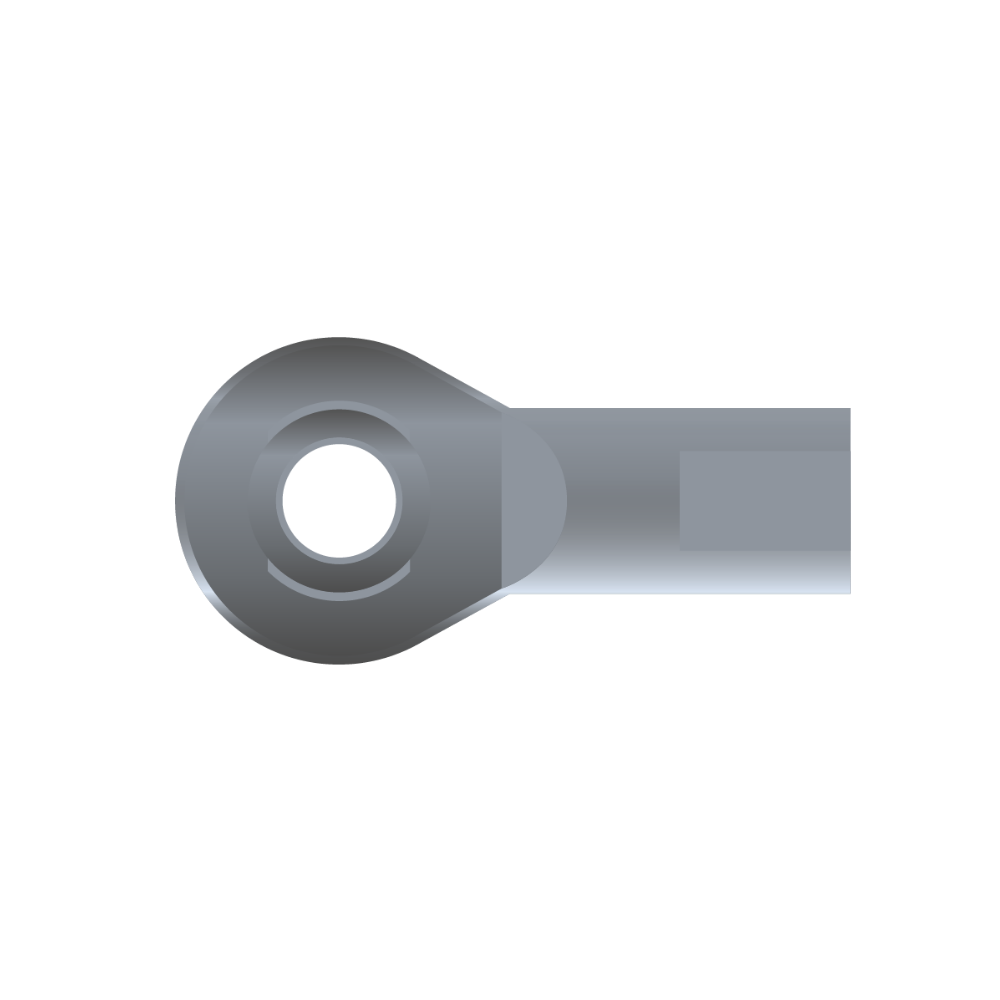

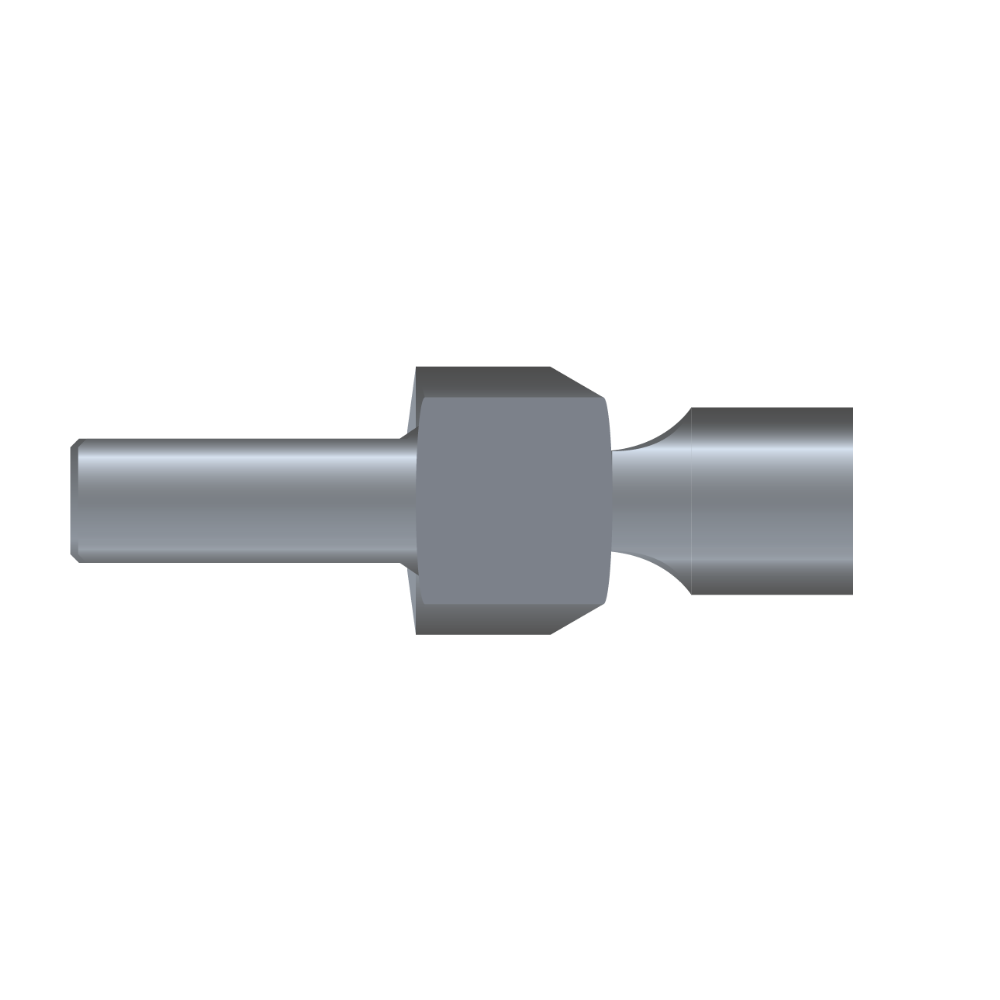

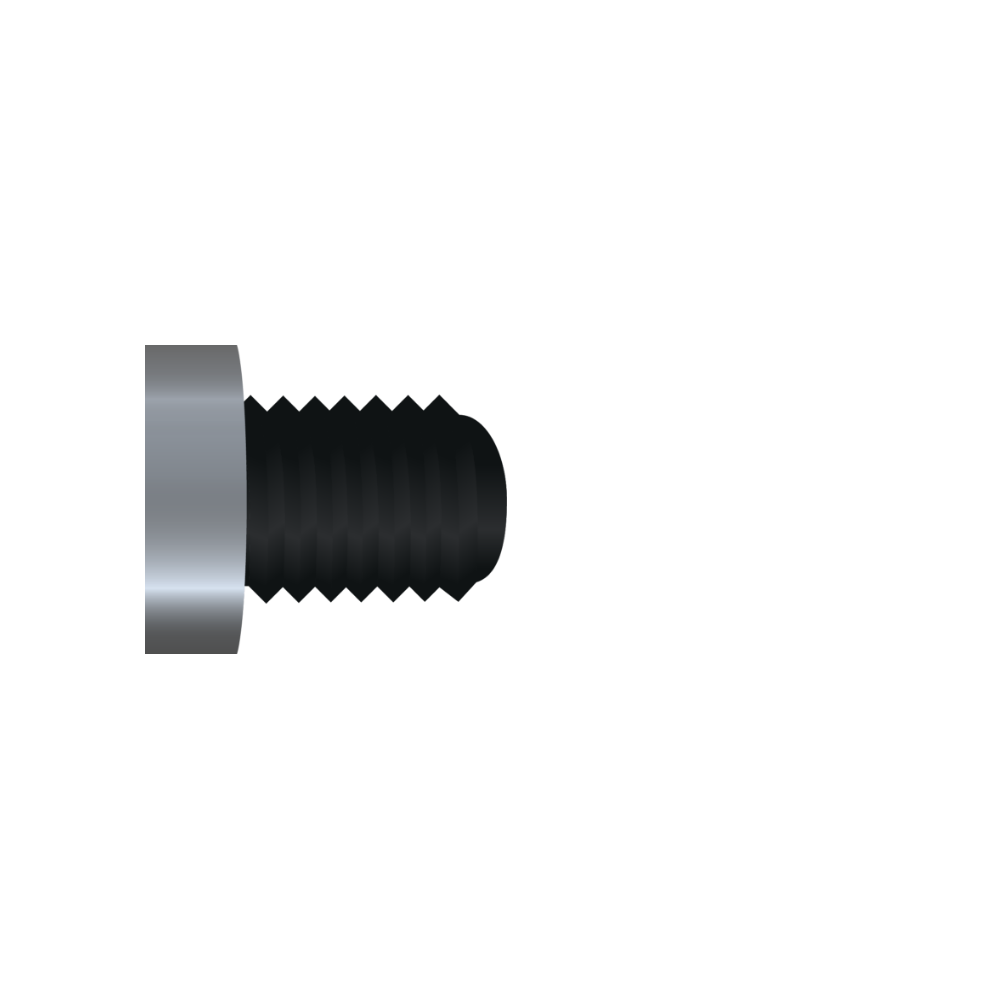

Bansbach Connecting parts

Bansbach release systems

Release System With Lever

Bowden Wire Release System

Hydraulic Release System

- 1Gas spring release head standard

- 2Pivot point

- 1aRelease lever (release direction towards spring)

- 2aRelease lever (release direction towards the spring)

- 1bRelease lever (release direction away from spring)

- 2bRelease lever (release direction away from spring)

construction

- 20AK08M8*1

- 20AKXXMXX

- 20AK10M10*1

- 20AK12M10*1

- 20AK12M14*1,5

- 20AK14M14*1,5

inpull direction

- 7.000

- 7.000

- 12.000

- 12.000

- 12.000

- 12.000

- 37

- 37

- 54

- 54

- 54

- 54

- 30

- 30

- 39

- 39

- 39

- 39

- 38

- 40

- 50

- 50

- 50

- 50

- R8,5

- R8,5

- R14

- R14

- R14

- R14

- 8,1-0,05

- 10,1-0,05

- 10,1-0,05

- 12,1-0,05

- 12,1-0,05

- 14,1-0,05

- 17

- 17

- 21

- 21

- 21

- 21

- SW11

- SW11

- SW14

- SW14

- SW14

- SW14

- 20

- 20

- 26

- 26

- 26

- 26

- 38.5

- 38.5

- 53

- 53

- 53

- 53

- M8*1

- M10*1

- M10*1

- M10*1

- M14*1.5

- M14*1.5

- SW13

- SW17

- SW17

- SW17

- SW19

- SW19

- 9

- 7

- 8

- 8

- 8

- 8

Bansbach Recommendation for installation

The installation recommendations can be changed in the sidebar.reits Routine.

-

Within the ranges shown, you can select your optimum dimension yourself. The tolerance for the installation lengths is generally ± 2.5 mm, within a series production a manufacturing tolerance of max. ± 1 mm applies. For high demands on durability and stability, please avoid the combination: small diameter + long stroke + high force.

-

Damping characteristics can generate vibrations that find a resonant body in the application, causing noise. Small changes to the installation, fasteners or tuning can remedy the situation.

-

Bansbach gas springs have been designed and tested for the highest requirements and greatest possible reliability. Installation recommendations and our comprehensive advice will support you in the selection of your individual gas springs.

But: The suitability test for the respective application is always the responsibility of the user! Products which are unsuitable for the application and defective products must not be used. We therefore exclude any liability for the functionality and service life of your end product.

-

Bansbach gas springs are manufactured to order – from mostly stock components. Cancellation, subsequent modification, exchange or return is therefore not possible.

-

If gas springs are sent in for detailed inspection, this constitutes consent to the destruction of this part, and the right of ownership thereby expires. Return of individual components is not possible. If necessary, mark submissions with e.g. “For functional test and with request for return”. If there is no objection, gas springs sent in will be disposed of 1 week after notification of the test result.

As a general rule: For unjustified complaints we reserve the right to charge a lump sum or the actual costs for processing and disposal.

-

Warranty claims expire in principle no later than 1 year after the date of manufacture of the gas spring. Manufacturing defects or quality defects in the gas spring can be detected immediately. If you are not satisfied with the delivered quality of the gas spring for a particular reason, please return it immediately. Please enclose the reason and an original copy of the invoice!

-

Bansbach gas springs can be stored in any position. Pressure loss of the gas spring due to long storage is not to be expected. No negative empirical values are available. However, sticking effects can occur, which require a higher effort when the gas spring is actuated for the first time (breakaway force).

-

The piston rod must be protected from impact, scratches and contamination – especially paint application. The cylinder tube must not be deformed. Damage to the surface will destroy the gas spring sealing system.

-

Gas springs are maintenance-free. Do not grease or oil the piston rod.

-

If gas springs are damaged visibly (broken or deformed connecting parts, bended piston rod, dented cylinder) due to external cause (accident, collision, extreme overloading,…) the pressure has to be released before the gas spring is being dismantled or used.

Please note our disposal and recycling instructions!

-

Gas springs should not be exposed to any tilting or sideforces during operation. If this is unavoid able, please check the installation and use suitable connecting parts.

-

Gas springs should be installed with the piston rod downwards. This position ensures the best damping effect. Only Bansbach gas springs include an integrated grease chamber which allows different directions of installation.

-

Bansbach gas springs can be used generally as a limit stop in both directions. The occuring forces should not exceed the following approximate values.

Series- 3/8

- 3/10

- 4/12

- 6/15

- 6/15 Niro

- 6/19

- 8/19

- 8/19 Niro

- 8/20 Alu

- 8/22

- 8/28

- 10/22

- 10/22 Niro

- 10/28

- 10/28 Niro

- 10/40

- 12/28

- 12/40

- 14/28

- 14/28 Niro

- 14/40

- 16/28

- 20/40

max. Force (N)- 600

- 600

- 1.500

- 2.500

- 1.750

- 2.000

- 5.000

- 3.000

- 3.500

- 5.000

- 7.000

- 5.500

- 3.000

- 8.500

- 6.500

- 7.000

- 9.250

- 12.500

- 7.000

- 7.000

- 6.250

- 15.000

- 10.000

This isn’t valid for lockable gas springs and traction springs!

Attention: The figures refer to the average pressure range of the respective size.

Some connectors such as elbow joints may not be suitable for the above values.

In case of high limit stop forces as well as for permanent load, we recommend an additional mechanical limit stop.

In case of reaching the limit range or a permanent use as limit stop please contact Bansbach easylift.

-

All gas springs are labeled with the warning „Do not open, high pressure“, the part number and the production date. If these dates are unreadable (removed, painting of the gas springs or any other influences) we refuse the liability for damages which result from this fact. Warranties aren’t possible anymore.

-

Disposal / recycling: Gas springs are mainly made of metal and can be recycled. However, the gas springs must be depressurised beforehand. Please request our disposal instructions for gas springs.

-

Gas springs are filled with pure nitrogen. Nitrogen is an inert gas, does not burn, does not explode and is not toxic. However: gas springs have a very high internal pressure (up to approx. 300 bar). Gas springs must never be opened without instructions!

-

Bansbach gas springs can be used at ambient temperatures from -30℃ to +80℃. For other temperature ranges (down to -55℃ or up to +200℃) special seal sets are available. For low-temperature ranges, detailed coordination of the requirements is necessary. The ambient temperature has an influence on the gas spring characteristics. Changes in extension force as well as damping characteristics are to be expected and should be tested in advance under application conditions. Do not overheat gas springs or place them in an open fire! Other environmental conditions can also have a significant influence on the service life. Please take protective measures into consideration.

Gas springs are available in a number of different lengths, forces and variations. They are also available in highly corrosion-resisting material.

We mostly use high-quality stainless steel material (V4A i.e. AISI-no. 316L) for the production of the stainless steel gas springs. They are not only resistant to water but are commonly found in food, chemical and salt water applications. If requested, some sizes of the standard gas spring are available in V2A (AISI 304), too. Please see our connecting parts available in stainless. All gas springs in these high-quality product groups are made with a valve, with the exception of P-models and traction springs with damping.

With these products, there are our stainless steel springs:

Do you need help?

We are there for you

Contact personthe product is precisely adapted to your requirements in order to ensure optimal function. We are happy to support and advise you in the selection of the right product.

With our “Technical Support” you have a direct line to our technicians, who will competently assist you. If you have any questions about offers, availability or prices, our commercial support will be happy to assist you.

Step by step to the individual product

The Bansbach gas spring configurator offers

you the possibility to put together your individual

gas spring from various components

even more easily and quickly.

Bansbach easylift

- » High-quality stainless steel material (V4A, AISI No. 316L)

- » Water resistant

- » Suitable for food, chemical and seawater applications

- » Connecting parts also made of stainless steel

Bansbach

Quality

Bansbach products are manufactured exclusively from high-quality, environmentally friendly materials. By continuously monitoring raw materials, carrying out test programmes and monitoring quality during the manufacturing process, consistently high quality can be guaranteed.

FAQs

Are Bansbach gas springs ROHS compliant?

Yes, they are fully ROHS compliant and also meet all guidelines, export/import regulations and goals of other company programs that we are aware of.

Can a gas spring made to customer specifications be returned?

Bansbach gas springs are manufactured to order – from mostly stock components. Cancellation, exchange or return is therefore not possible.

In case of free delivery, we will gladly take over the disposal – without charge – for you.

Can gas springs be disposed of in household waste?

No, gas springs are mainly made of metal. Please observe our disposal instructions.

Can gas springs be used in the food industry?

With the high-quality stainless steel gas springs in V4A, the high requirements of the food industry are met. Food-grade oil (FDA oil) is optionally available.

Can the speed/damping of the gas spring be influenced?

By selecting the appropriate nozzle bore and oil viscosity, the speed and damping of the gas spring can be adapted to the application.

Do Bansbach gas springs have to be stored with the piston rod pointing downwards?

Bansbach gas springs can be stored in any position.

Does a gas spring need to be protected from dirt?

The piston rod must be protected against impact, scratches and contamination – especially paint application. Damage to the surface will destroy the sealing system. If necessary, a wiper or a protective tube should be provided.

Does a gas spring need to be serviced?

No, Bansbach gas springs are maintenance-free. The piston rod must not be greased or oiled.

How do I find my personal contact person?

Bansbach easylift GmbH

Bararossastrasse 8

D-73547 Lorch

Phone: +49 (0) 7172/9107-0

Fax: +49 (0) 7172/9107-44

E-Mail: info@bansbach.de

You can find a contact person on site

Contact form

How high can the internal pressure of a gas spring be?

Depending on the series and the desired extension force, this can be up to approx. 300 bar.

How much is the weight of a gas spring?

Due to the wide range of products, the weights vary greatly.

Diameter piston rod / cylinder:

Ø3/8; Ø4/12; Ø6/15; Ø6/19; Ø6/22; Ø8/19; Ø8/22

Weight

100 g – 500 g

———-

Diameter piston rod / cylinder:

Ø8/28; Ø10/22; Ø10/28; Ø12/28; Ø14/28

Weight

200 g – 1000 g

———-

Diameter piston rod / cylinder:

Ø16/28; Ø10/40; Ø12/40; Ø14/40; Ø20/40; Ø30/70

Weight

500 g – 8000 g

In which colors are Bansbach gas springs available?

The piston rod and the cylinder are supplied in black (standard).

On request, our cylinders are available in all RAL colors. Exception: stainless steel

In which temperature ranges can Bansbach gas springs be used?

For ambient temperatures from -30°C to +80°C.

For other temperature ranges (down to -55°C or up to +200°C) special seal sets are available.

Is it possible to repair a gas spring?

No, because it is a closed system that is under high pressure and must not be opened.

Is the extension force of the gas spring temperature-dependent?

For physical reasons, the extension force of the gas spring changes by approx. 3.3% per 10°C (base + 20°C).

What does the index number (e.g. – -001/100 N) at the end of the article designation of the gas spring mean?

This is a code assigned internally by Bansbach for unambiguous reproducibility of the gas spring.

What materials are Bansbach gas springs made of?

Gas springs consist of piston rod, cylinder tube, connecting parts, turned parts, seals, oil, grease and nitrogen. Piston rods and cylinder tubes are made of steel and are CeramPro® or powder coated in our company. Connecting parts and turned parts are made of lead-free steel or lead-free aluminum.

Seals, oils, greases do not contain substances that are on the list of critical or hazardous substances. Nitrogen is an inert gas that neither burns nor poses any other health hazards. Bansbach gas springs therefore comply with current and, as far as we know, planned laws and regulations.

They comply for example with the RoHS Directive, WEEE Directive, Directives 2003/11/EC, 2002/95/EC, 2002/96/EC. They are not covered by Directives 94/9/EC, 97/23/EC, and 98/37/EC, nor by UN 3164, TRGS 220, and UL 60601-1.

Verification that Bansbach gas springs in the end product comply with national or international laws and regulations remains the responsibility of our customers or the user.

What service life/running performance can I expect from a Bansbach gas spring?

On average, Bansbach gas springs are designed for 50,000 – 100,000 double strokes.

Depending on the design, installation and effective stroke, several 100,000 strokes can also be achieved.

For other products please contact us.

Which stroke lengths are possible for the gas springs?

Depending on the series and design of the gas spring, the stroke length can be freely selected between 10 mm and 1000 mm. Other variations possible, please contact us.

With our “Technical Support” you have a direct line to our technicians, who will competently assist you. If you have questions about offers, availability or prices, our commercial support will be happy to assist you.